PG x Lantal

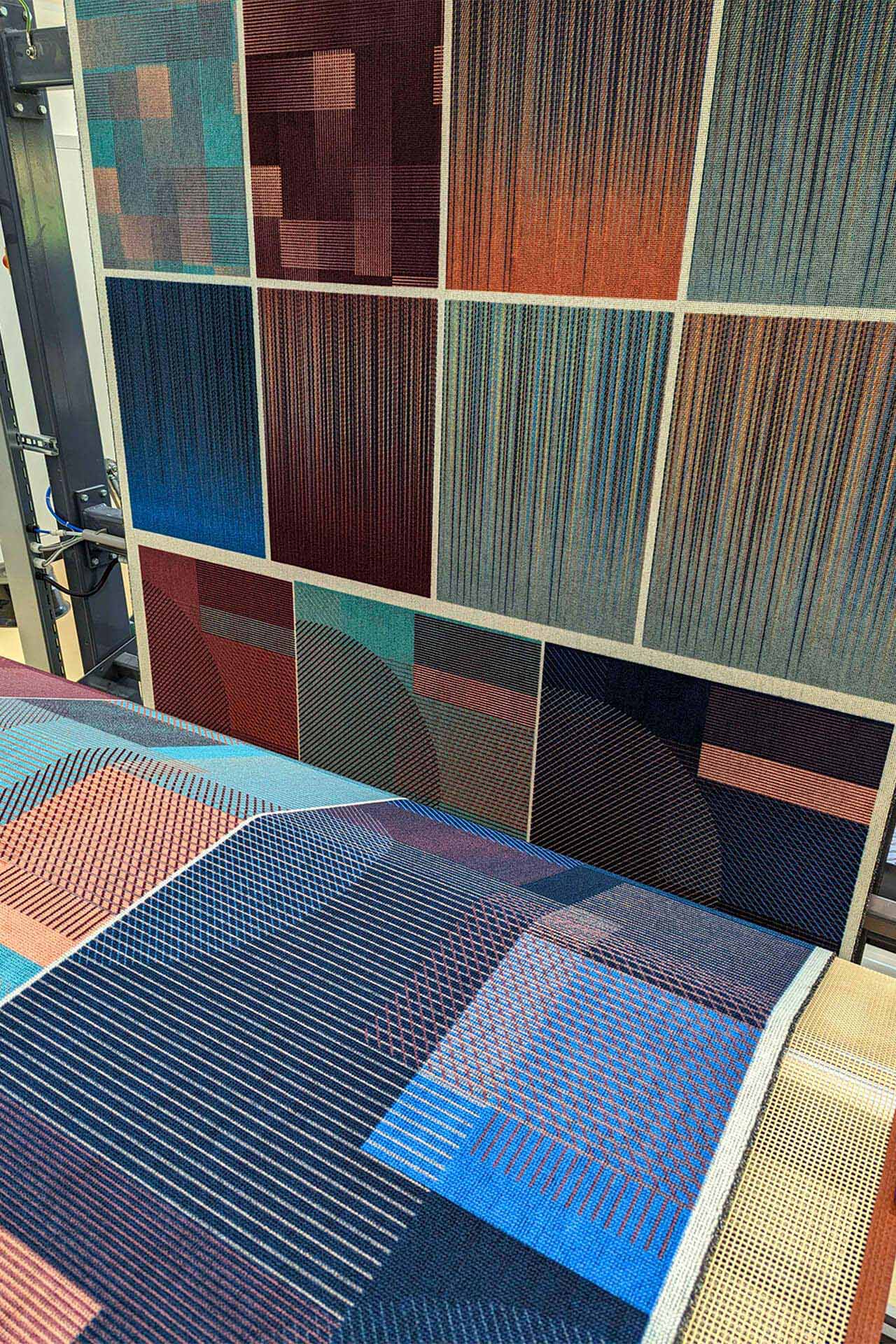

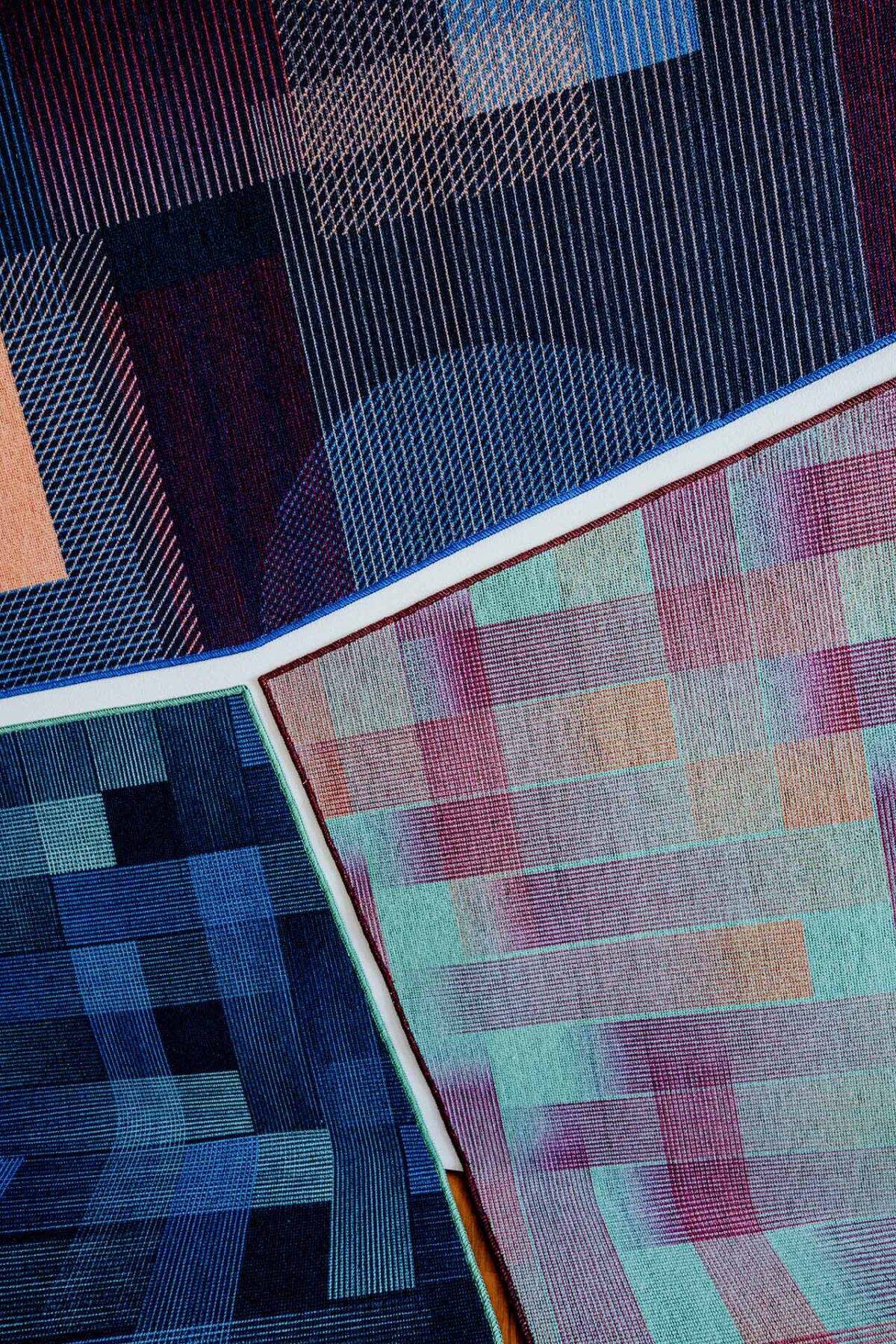

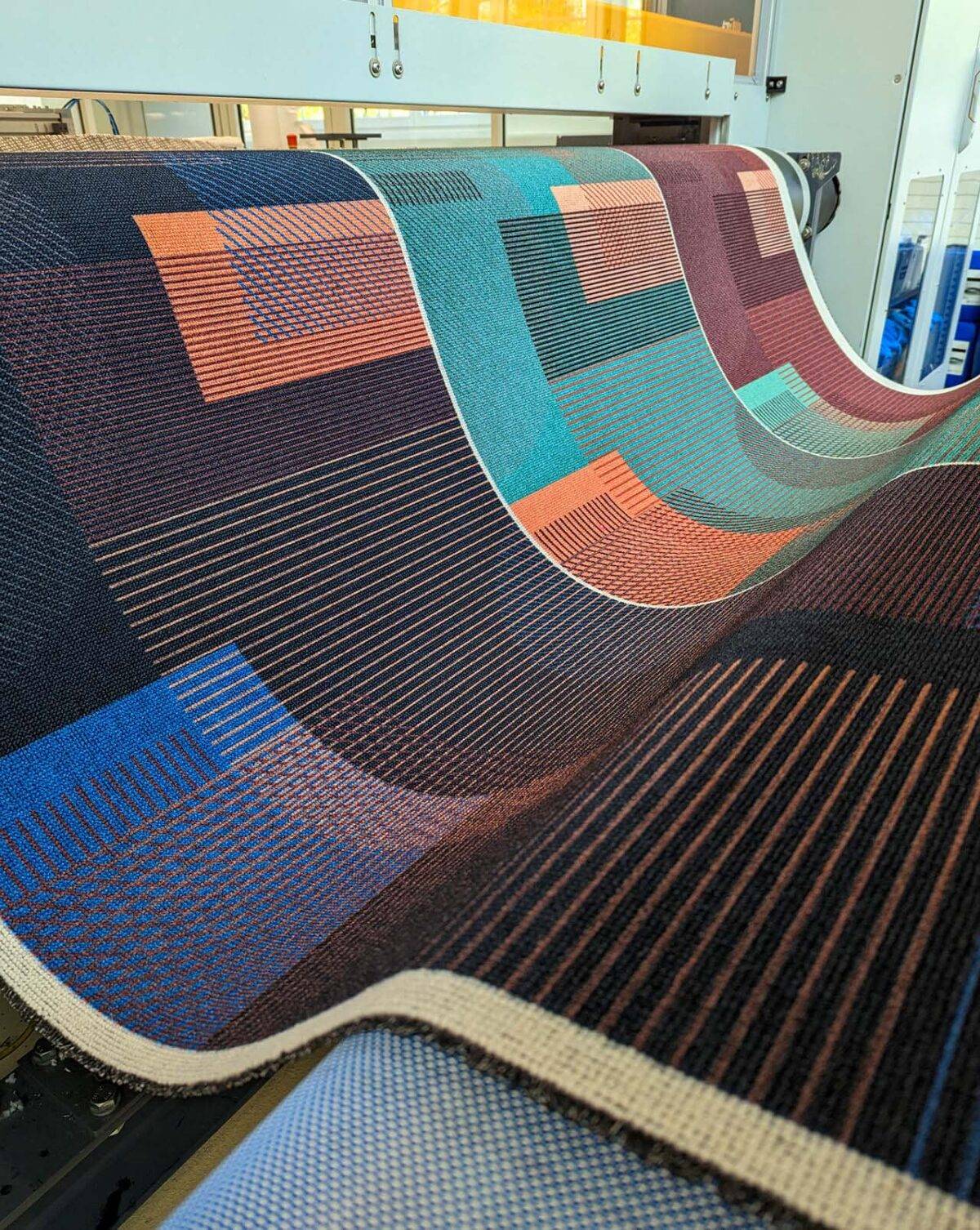

Collaboration towards net zero in aviation. PG collaborated with Lantal, exploring their award-winning DEEP DYEING CARPET technology to produce a new set of carpet designs. The revolutionary process supports increasing demand in aviation for lightweight, durable materials that are still highly customisable at low minimum order quantities, with reduced waste in manufacture.

Challenge

As the aviation industry makes progress towards net zero by 2050 or sooner in some cases, the reduction of waste in the manufacture of materials will contribute towards that goal. Route to Zero, the process that PriestmanGoode has established as part of our role in guiding our clients towards more sustainable options, recognises the need to reduce, reuse and rethink current processes to enable a more sustainable future industry. In live projects, timescales are often fixed with limited time available for the development of sustainable alternatives. Therefore we welcomed the invitation from our material partner Lantal to explore the endless possibilities presented by their DEEP DYED Carpet, the Crystal Cabin award-winning process that facilitates the production and hyper-personalisation of carpets ‘on demand’ with greatly reduced waste and no compromises compared to traditionally woven carpets. PG were asked to design a collection that keeps traditional and realistic aesthetics alive, but with the future in mind using alternative processes as part of an exciting digital future.

Solution

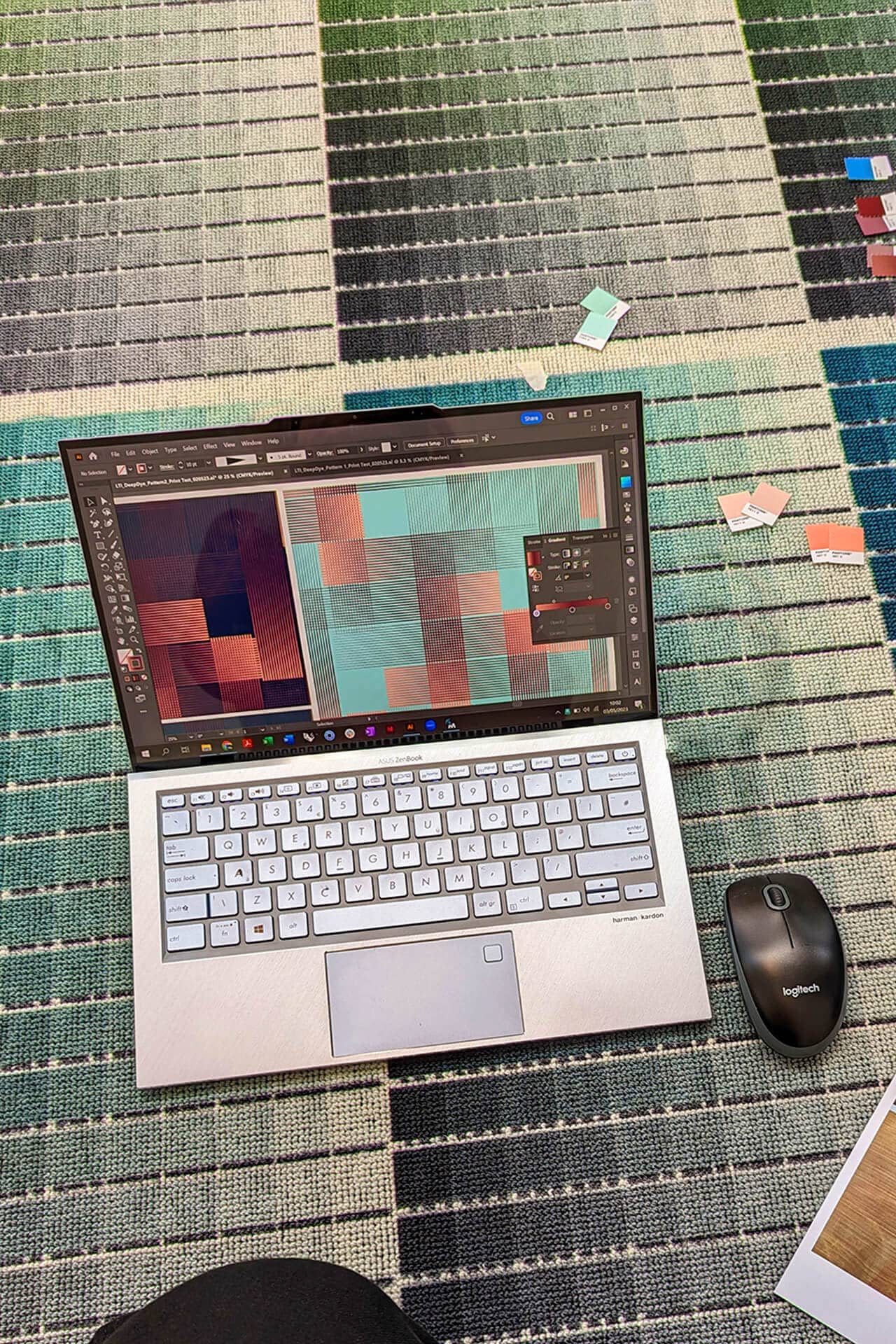

In response to the open brief from Lantal, our approach was to explore the possibilities of the technology to the maximum, creating a variety of designs through colour and pattern, with the future in mind. Shaping a collection with a positive impact was a very motivating aspect of the challenge. As designers we recognise the influence we have at the beginning of the process in the selection of materials through our Route to Zero approach. As part of the advice we give to clients, we look for ways in which sampling processes can ultimately reduce waste, how the same materials might be reused after disassembly, and re-thinking the process to reduce aviation’s carbon footprint. The Colour, Material and Finish design approach quickly recognised how the technology behind DEEP DYED Carpet brings flexibility and speed to manufacture with greatly reduced waste, which is comparable to the use of 3D printing in modular design or zero waste pattern cutting that’s being adopted in fashion and other textile-led industries.

The discovery phase of the project included time at Lantal’s archive where the team were reminded of the textile provider’s legacy for joyous, bold, expressive and era-defining interiors, particularly in aviation. As a further aspect of the “anything’s possible approach” the team considered ways in which the technology opens possibilities to address some other major challenges facing society, such as designs that ‘work’ for all ages, physical abilities and genders. Colour combinations were identified with a positive impact on well-being and supporting those with visual impairments.

The three themes that ran through the final collection are as follow:

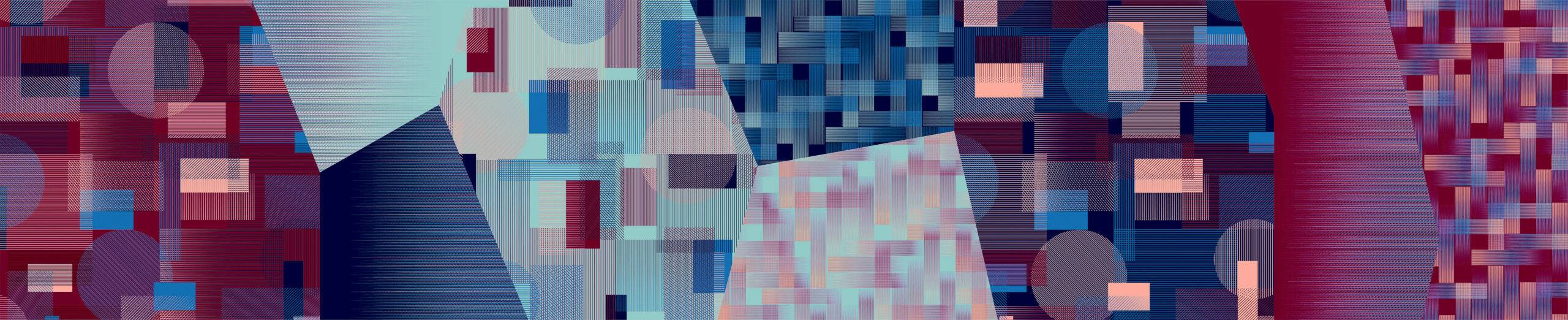

- Maximalist energy – a design that embraces the endless possibilities of the technology and showcasing this in a positive, energetic manner to spark the imagination of others.

- Nostalgic heritage – drawing inspiration from Lantal’s legacy and acknowledging the need to design with longevity in mind to create a long lasting appeal across markets to emphasize the sustainable benefits of DEEP DYED.

- Earthscape colours – reminding us that we’re connected by our planet and showing how design can encompass the needs of all, through a common threat of colours inspired by our earthscape.

“In a traditional sampling process for aviation clients, a minimum production of 5 metres of carpet is necessary in order to present a single sample. The new process reduces waste in production dramatically, but no aspect of the traditional process is compromised in any way.”

MARIA KAFEL-BENTKOWSKA, HEAD OF COLOUR, MATERIAL AND FINISH AT PRIESTMANGOODE

“Our goal was to develop an iconic yet sustainable aviation carpet collection. It has been an inspiring journey to work with PriestmanGoode. Pushing the design and technology to another level with PG has been an outstanding experience, oftentimes exceeding our expectations. We love the outcome!”

LUZIUS RICKENBACHER, EVP AVIATION INTERIORS AT LANTAL

AWARDS

London Design Awards 2023, Better Future – Circular Economy, Gold award